It's Easy & Quickly for Electronic Enclosures

Design and Manufacturing.

Custom Electronic Enclosures Experts in Industry

Let's Talk About Your Electronic Enclosures Solution

Plastic Electronic Enclosure Solutions

Electronic enclosures keep your components protected in any environment. Hongfa Case offers an array of electronics boxes and multi-purpose metal and plastic electronic enclosures. Superior materials include high-quality plastic, aluminum, and steel varieties, with indoor and outdoor electronics enclosure options available. From robust NEMA rated enclosures to basic potting boxes, find your perfect fit at Hongfa Case.

Electronic Enclosure Manufacturer in China, 25 Years Experience.

- Turn Key Services Available.

- AS9100 & ISO Certs

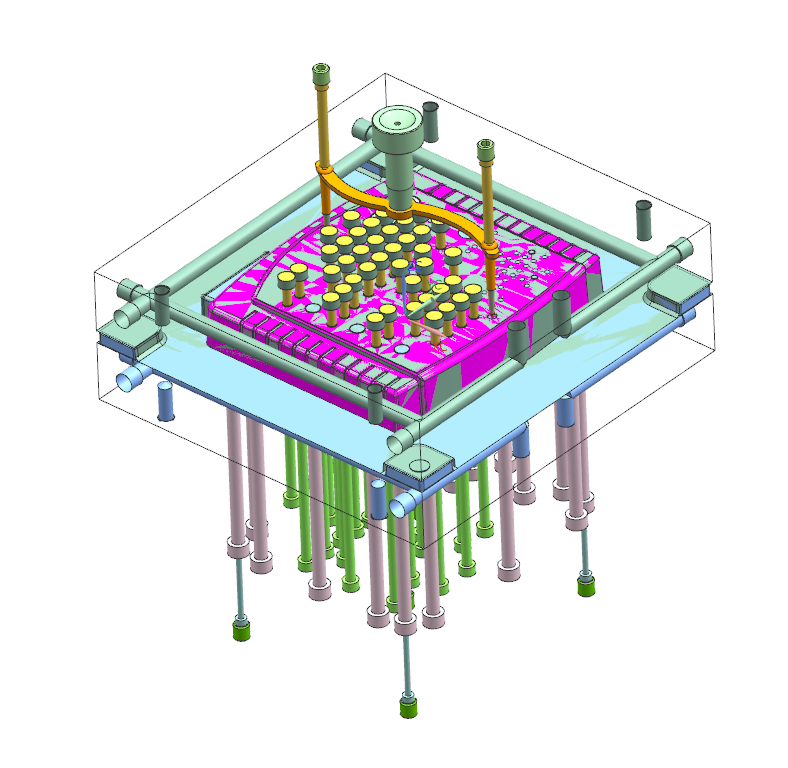

Electronic Enclosures Design & Manufacturing

Hongfa is mainly engaged in the design and marketing of the mould for the hardware and plastic enclosure. At present, there are over 30 series and nearly 3000 kinds of hardware and plastic shells, covering extruded aluminum enclosure, aluminium heat sink parts,sheet metal case, plastic enclosures.

Custom Electronic Enclosures Expert, Delivery Quickly and Professional Quality

Whether you’re looking for OEM, benchtop, or engineered solutions, you’ll find that when you talk, our team listens. Then we foster working relationships that save you time, money, and resources — so you can focus on doing what you do best.

Worldwide, thousands of manufacturers, including Fortune 100 Companies , have lived The HONGFA Experience, succeeding with our standard and engineered-to-order automated laser part marking systems. Isn’t it time you experienced it for yourself?

Plastic Enclosures For Electronics Equipment

Smart, Modern Plastic Enclosures For OEM Electronics.

It’s time to find an electronic Enclosures partner

- Who can design innovative solutions

- Who has the engineering skill and expertise to create results

- Can move your project out of prototype and into the market

From legacy projects to the latest technologies, Hongfa Case is the manufacturing and Design partner you need on your team.

electronics enclosure design and Manufacturing

We offer high-quality electronic enclosures design and manufacturing. Hongfa pride’s itself on our commitment to our customer satisfaction.

Hongfa Case is a electronic enclosures manufacturer you’ve been looking for. We are proud of our quality certifications that offer you turnkey solutions for your electronic manufacturing needs.

Contact us today to learn more about how Hongfa Case is the electronic contract manufacturing partner you’ve been searching for.

Custom

Extruded Aluminum Enclosure

Extruded aluminum enclosures are extremely useful for creating PCB enclosures,with nice appearance, easy to assemble.

Custom

Sheet Metal Parts

Fully finished precision sheet metal parts such as brackets, rack mount case, distribution case, and fully custom designs.

Custom

Plastic Enclosure

Hundreds of plastic enclosures for different applications,waterproof junction box,router enclosure,gas sensor case,din rail box etc.

TEAM UP WITH THE EXPERTS:

YOUR HONGFA EXPERIENCE

Since established in 2007, the company has been keeping the operating philosophy of ‘Honest, Innovative, Customer-oriented, Human-oriented, and Benefit-based’, following the operation strategy of ‘Quality, Innovation, and Services’ and taking the advantage of others to create benefit with high-efficiency management and to build up good corporation and support from new and old customers, with the efforts of all our staff, the company will surely become stronger and stronger.

Factory

LEARN ABOUT ENCLOSURE SAMPLE