DESIGN & PROFESSIONAL

Plastic injection molds and molding

Home > Plastic injection molds and molding

Plastic injection molds and molding

Our Services: 1) Custom Plastic injection molds 2) Molding

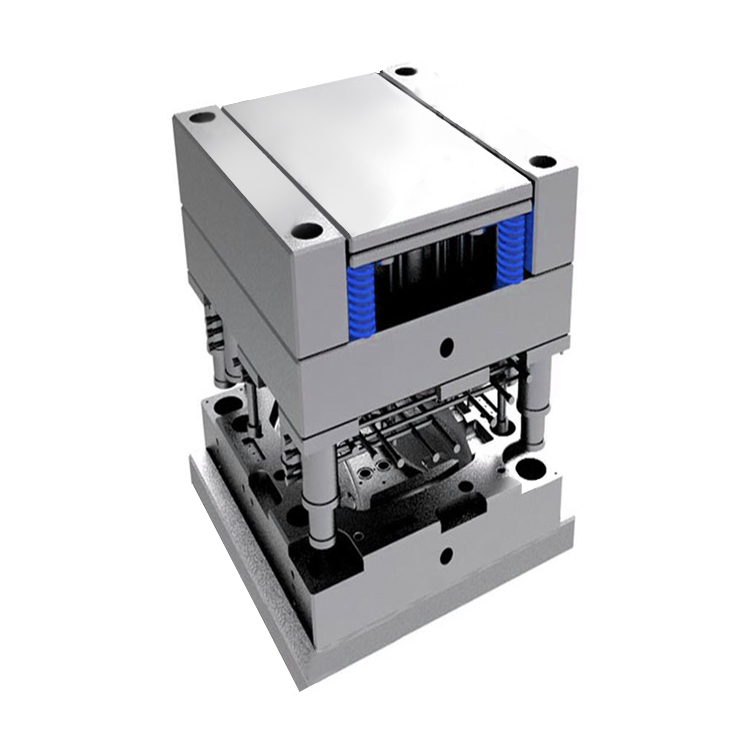

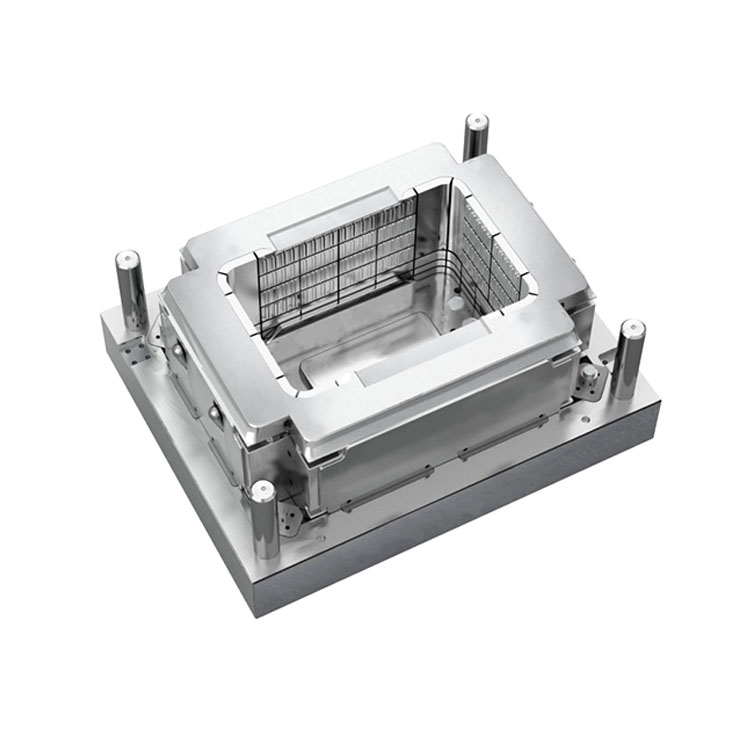

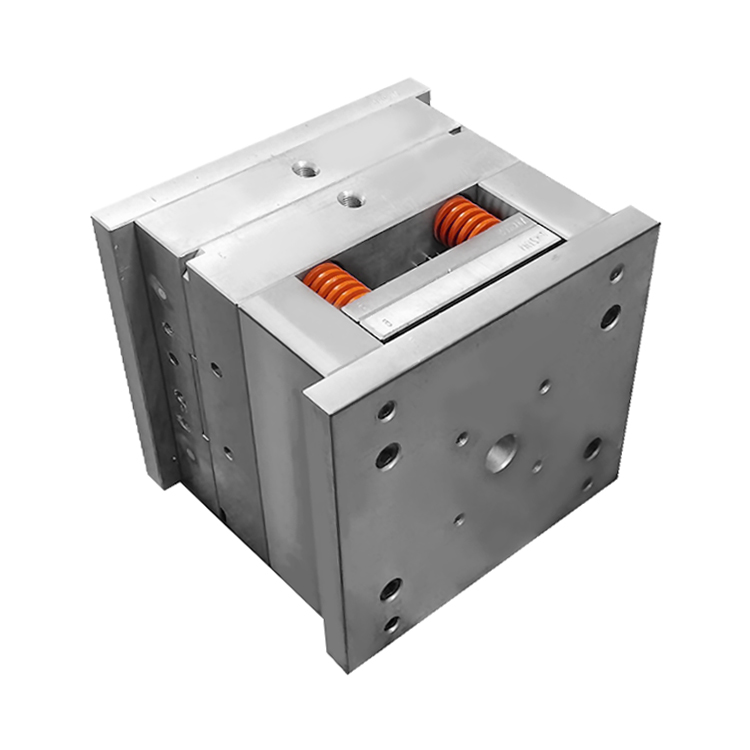

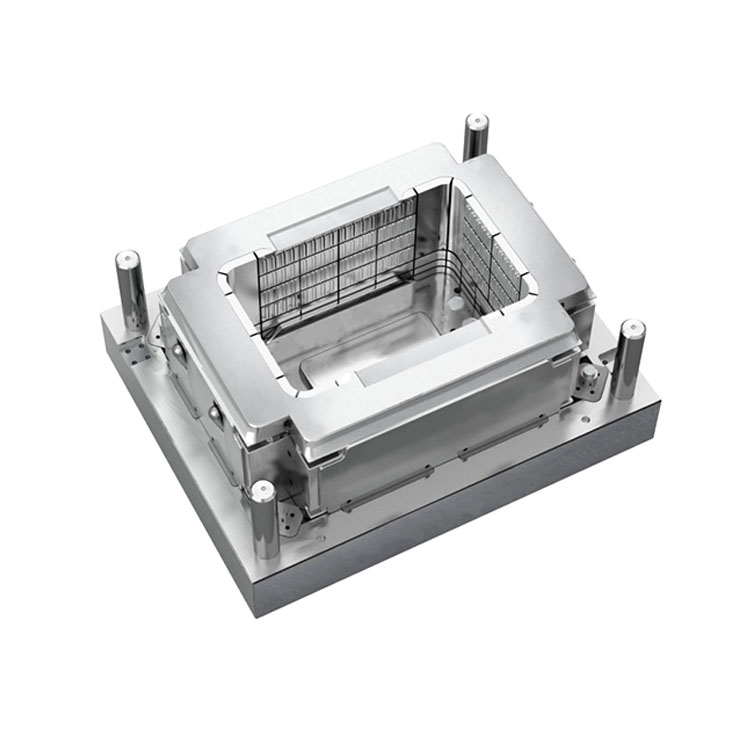

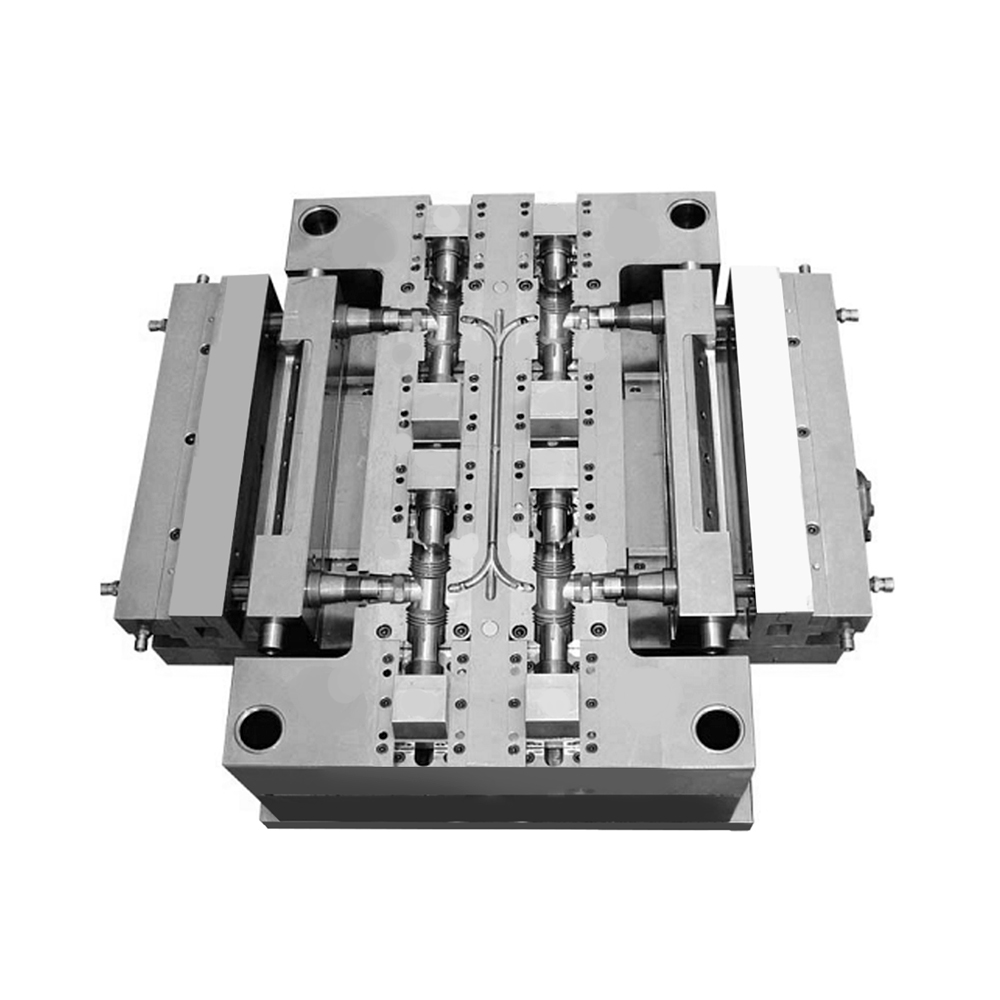

Custom Plastic injection molds

Hongfa is specialized in design and manufacturing of various types of plastic injection molds for plastic enclosures.With 20 years of experience and precision hardware machining technology, professional design and engineering team. We are confident that we can provide professional design and design guidance to our customers, and provide high quality products and services to meet their needs.

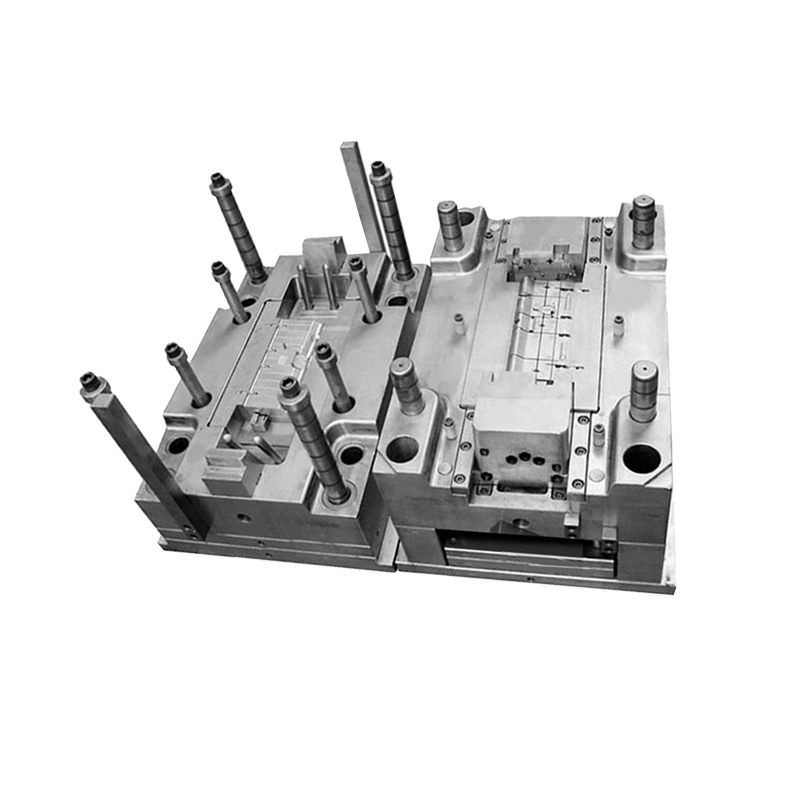

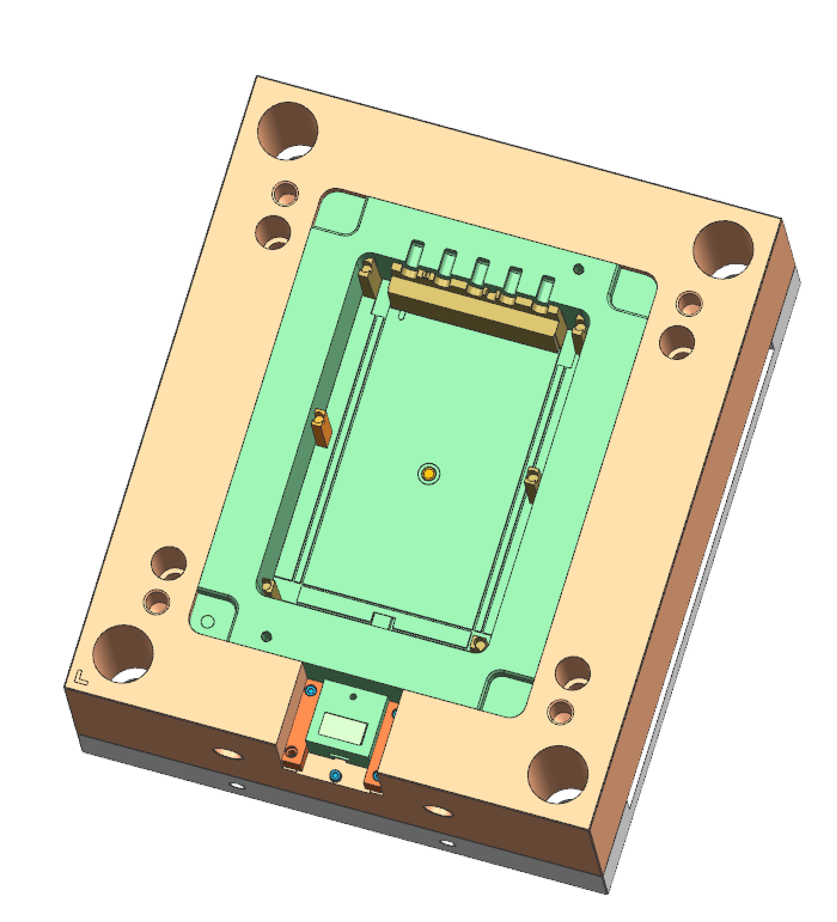

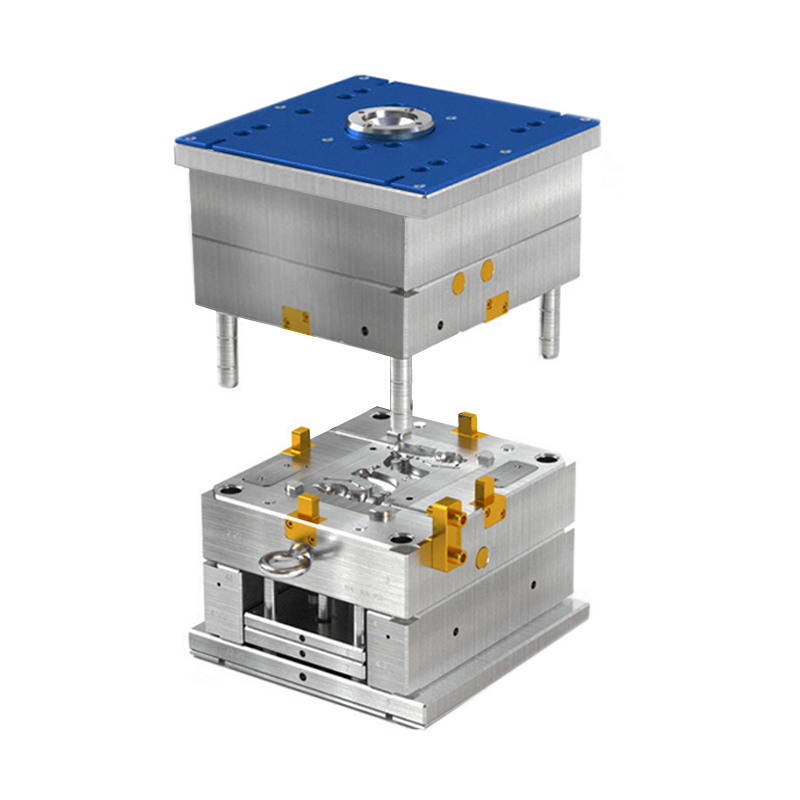

Plastic injection molds design

Hongfa has mold engineers with more than 10 years of experience to provide customers with professional mold design as well as product design guidance. Plastic mold design includes plastic shell product design, injection mold system design.

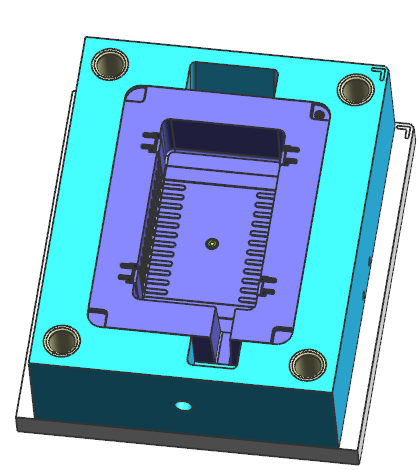

Plastic case product design mainly includes the structure design of the plastic case, our company can according to the electronic circuit board provided by the customer and the customer’s specific requirements, to design the customer needs the product shell.

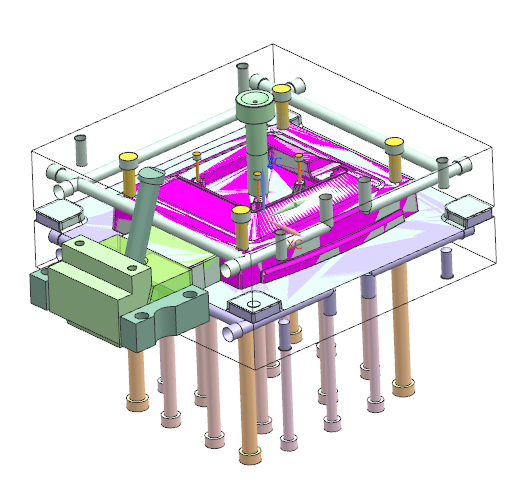

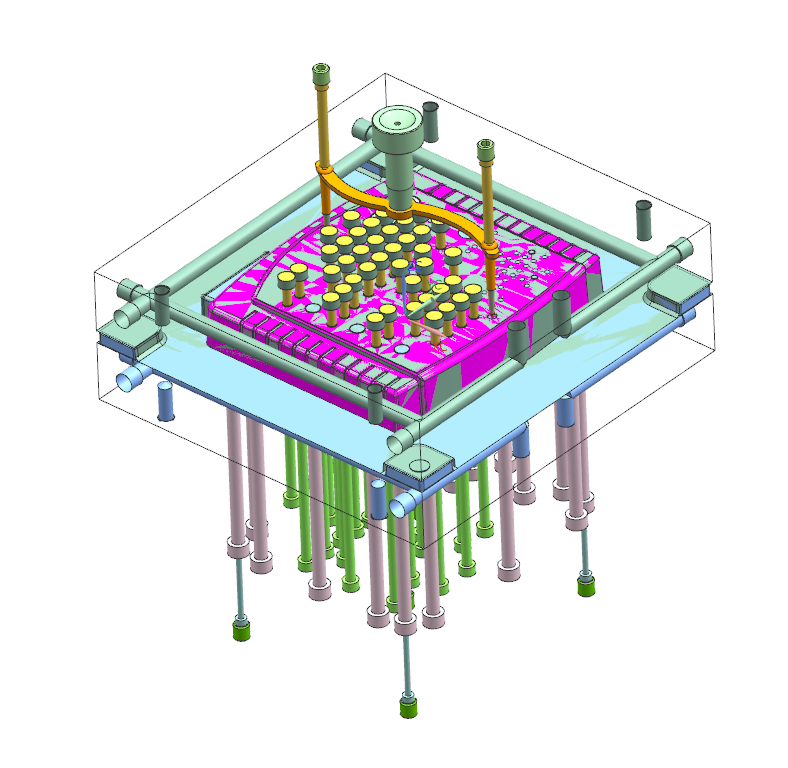

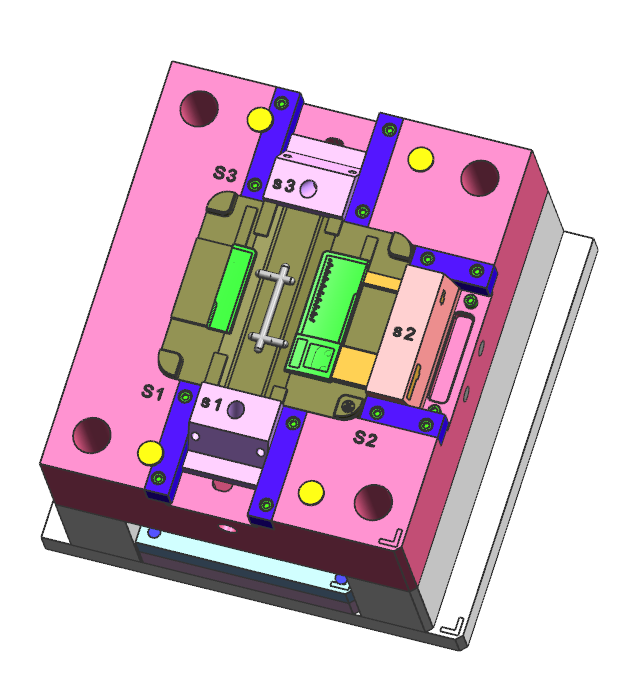

Plastic injection mold design includes the design of a whole injection mold, including mold frame, mold kernel, auxiliary parts, auxiliary systems, auxiliary settings and so on.

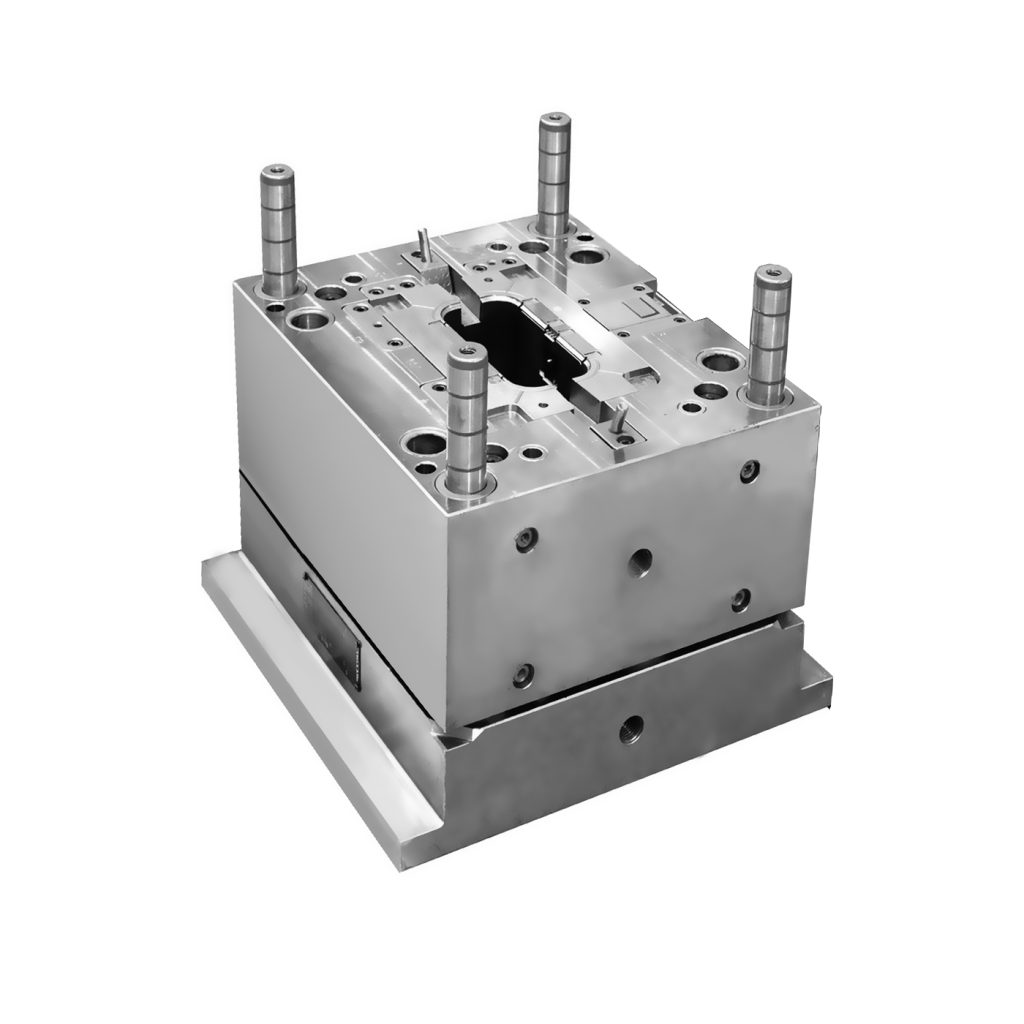

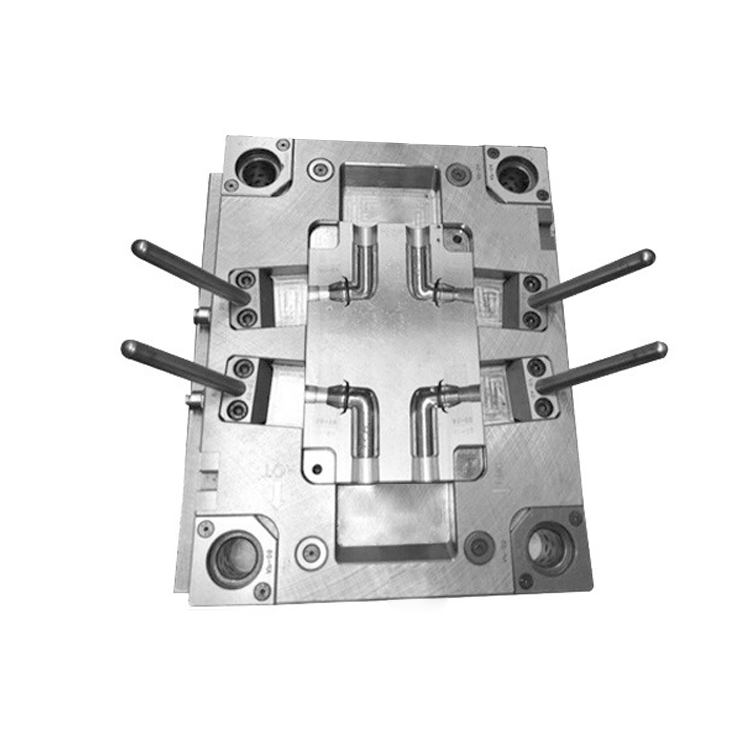

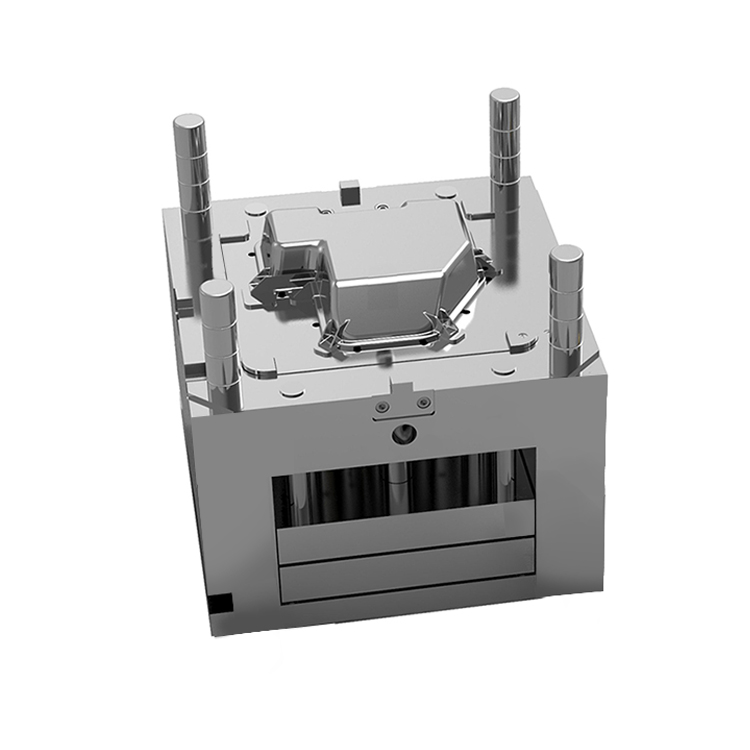

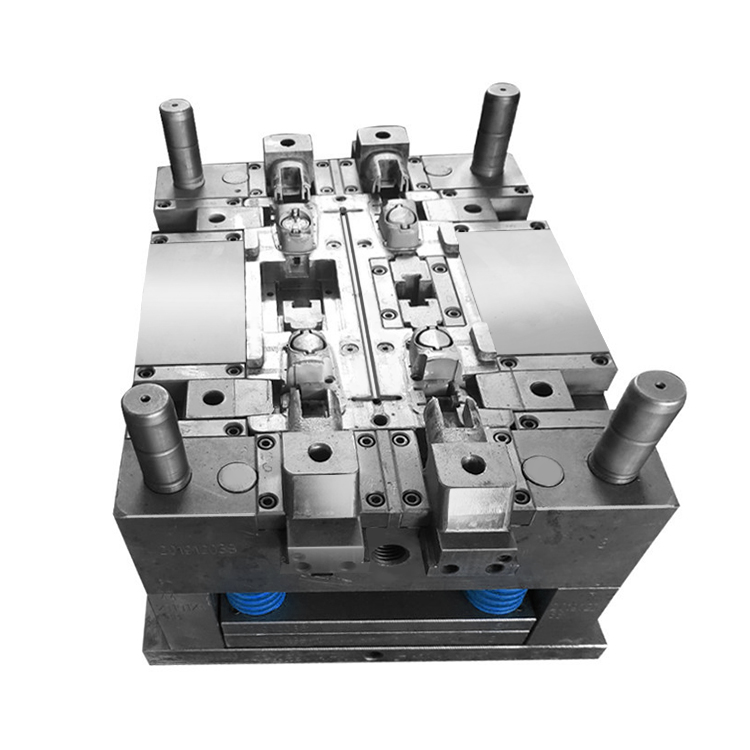

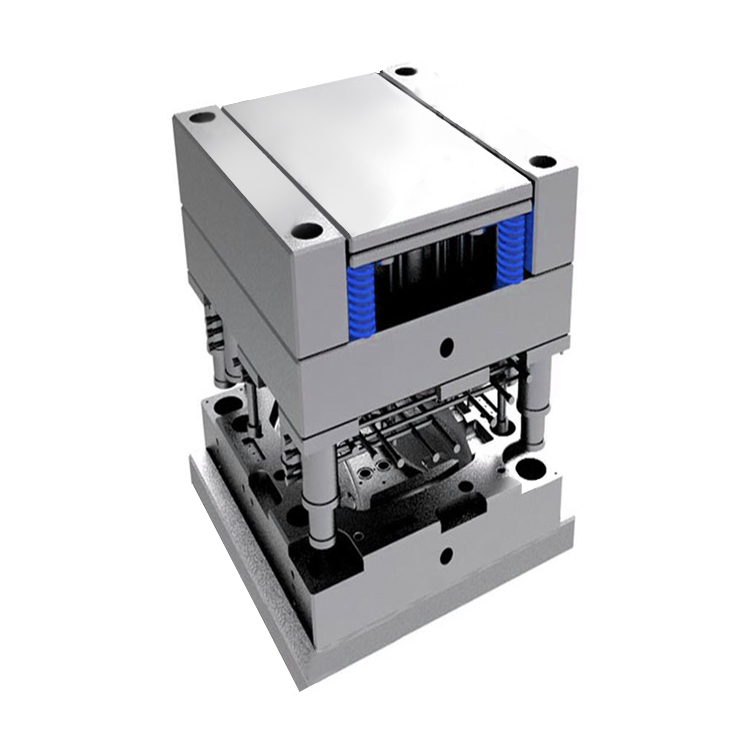

Injection Mold Cooling System Design

The gating system of injection mold plays a vital role in mold production and product quality. Whether the gating system design is reasonable or not has a direct impact on the quality of the products, including appearance, warping deformation, weld lines, flow marks, trapped gas and so on.

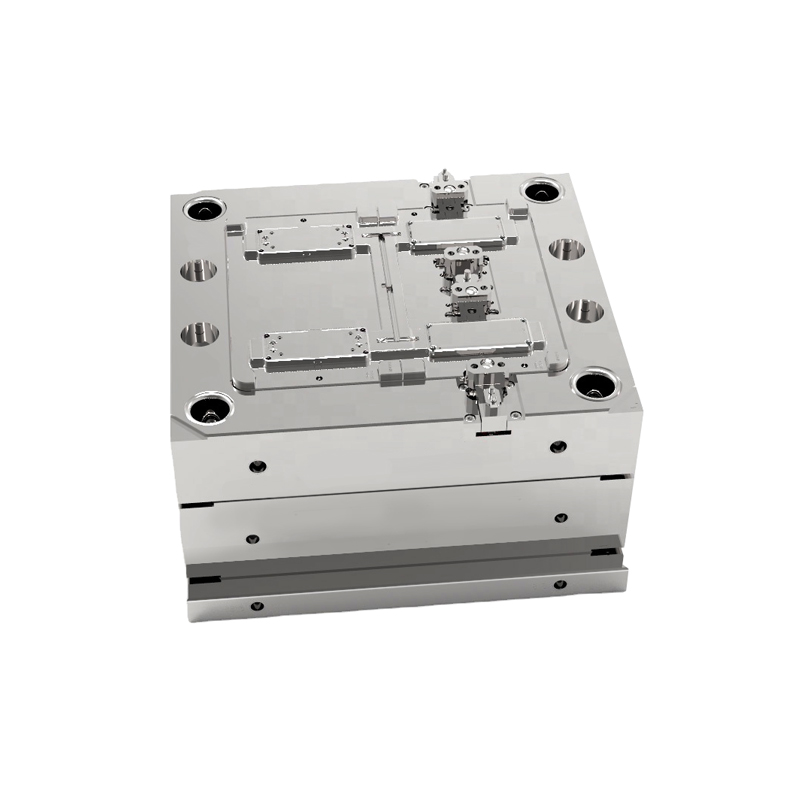

Injection Mold Cooling System Design

A well designed cooling system can significantly shorten the molding cycle, increase production capacity and reduce costs. Improper design of the cooling system will lengthen molding time, increase costs; uneven cooling will cause product warpage deformation and other undesirable.

Injection Molding System Design

Unreasonable design of the molding system will affect the mold-making cycle and injection molding cycle, as well as product appearance and performance. Thus, our engineers pay 100% attention to the design of core and cavity, ensuring the best product possible.

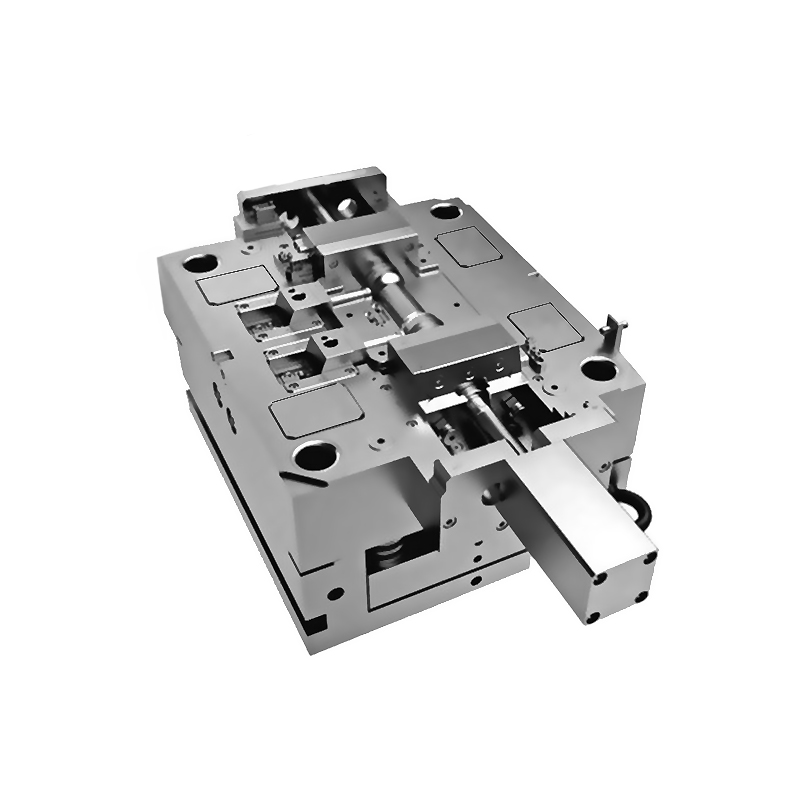

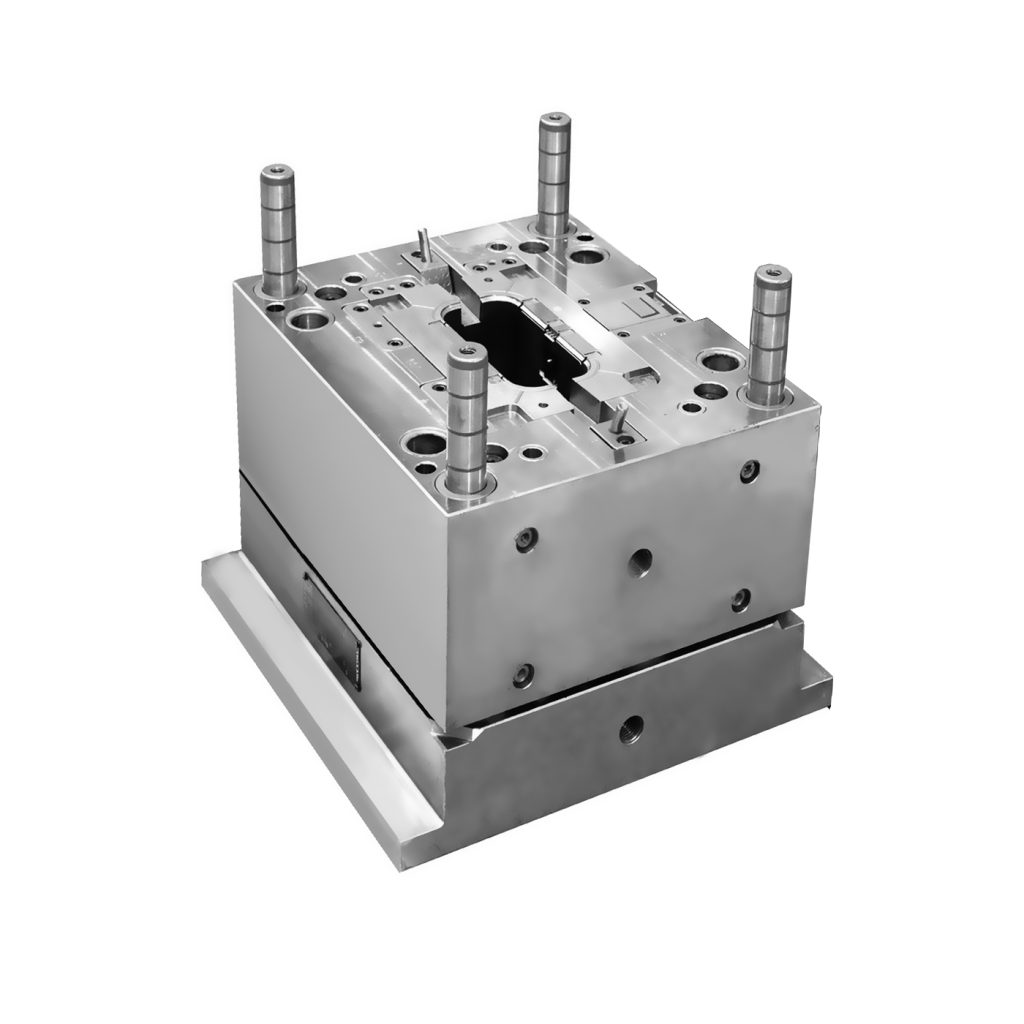

Ejection System Design

The ejection system will determine the appearance and performance of the final product, unreasonable ejection system will cause deformation, whitening, rupture and so on. With 20+ years of experience in mold design, Hongfa Shunda Mould got you covered.

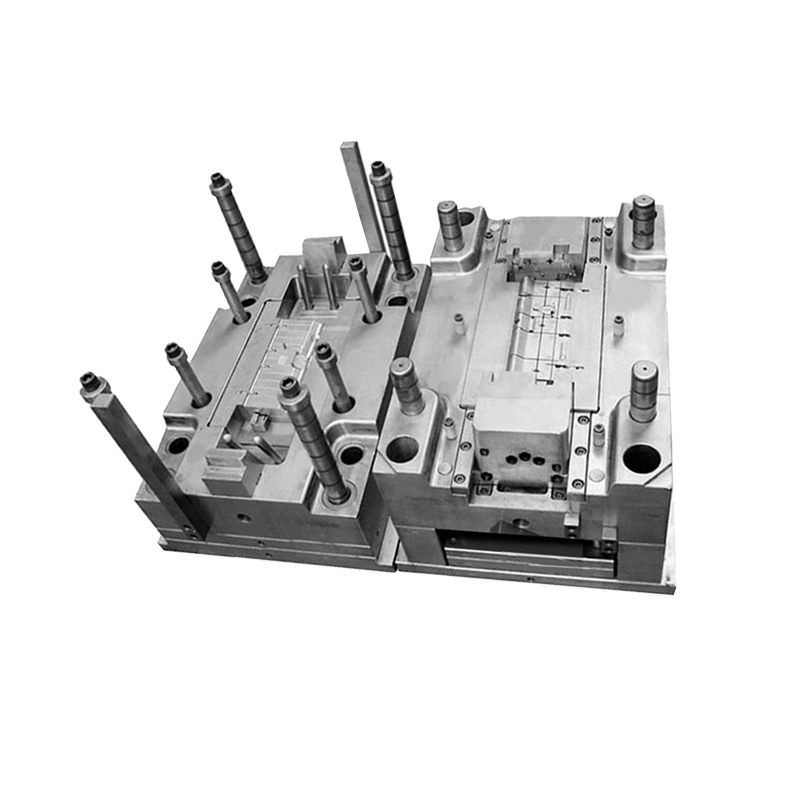

High Precise Plastic Injection Mold Making Service

High precise injection mould is to be achieved not only by the precise machines, also by the rich experienced technicians. Hongfa Shunda Mould a custom plastic injection mold manufacturer in China, imported lots of advanced machines from Switzerland, Germany, Japan, etc. The accuracy is +/- 0.01MM. Besides, our tool makers have rich experiences in molds area for more than 16+ years. Hongfa Shunda Mould is committed to providing our esteemed clients the high precision injection molds of any size or complexity.

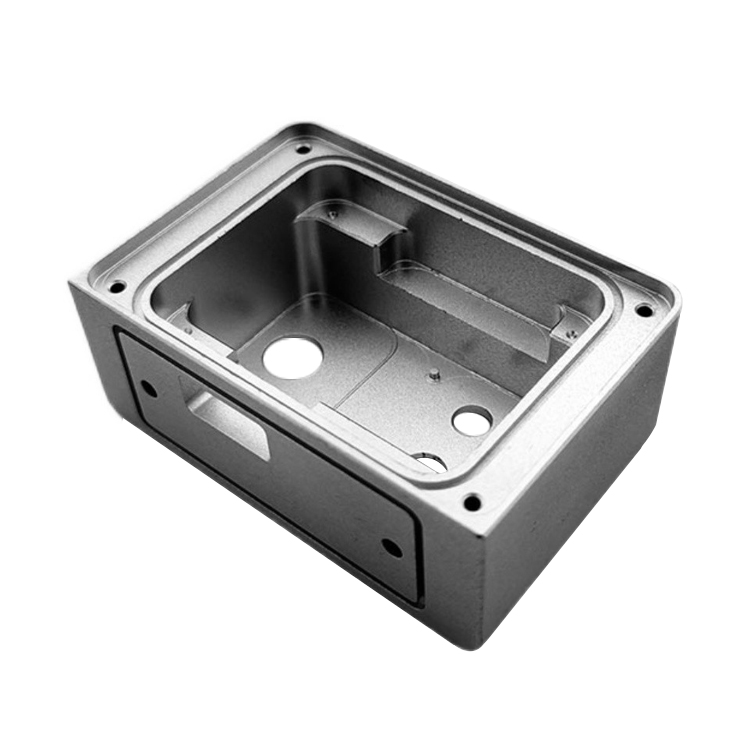

Plastic Injection Molding

Hongfa has an automated injection molding production line to provide customers with injection molding and processing of plastic housings.We have a strict quality control system for producing injection molded parts. We utilize scientific plastic injection molding techniques,which optimizes and fixs processing parameters to guarantee part consistency. We also give special consideration to critical-to-quality dimensions through our exclusive automated CMM process.

Also we have a stronge supply chain. All of our injection molding materials are procured directly from manufacturers or their authorized agents, ensuring that we can offer the finest materials for your project.All plastic raw materials are new and environmentally friendly materials, a full range, ABS PP PC PA66 Nylon POM HDPE PE PMMA PS

Why choose us as your custom enclosure suppliers?

For over 14 years, HONGFA has been a leader in the development of enclosures products for permanent marking and traceability. The demand from organizations to mark products continues to rise and spread to a wide range of industries opening a plethora of opportunities.

With systems installed globally, our customers’ continued loyalty is a testament to HONGFA’s service-minded culture. As much as we focus on customers, we also know that our employees are a vital component to the continued success and the future of HONGFA.

HONGFA wants each and every employee to be successful and develop their own rewarding career. That’s why one of our core values is pursuing personal and company growth, because we know that when you succeed, we all succeed.

OUR News & events

The first time know what happen in HONGFA company. We will update the last technology in custom aluminnum, meta and plasti enclosure.We design and manufacture custom enclosures for a wide range of industries and sectors. We are used to working towards specific norms and specifications.

GET TO KNOW MORE KNOWEDGE ABOUT ENCLOSURE

We offer two standard systems for enclosures of any dimension. To create these enclosures, Front Panel Designer includes a housing tool that enables you to create all the housing sections you need with just select the right accessories.