Global Delivery

CNC Turning Centers

Home > CNC Maching > CNC Turning

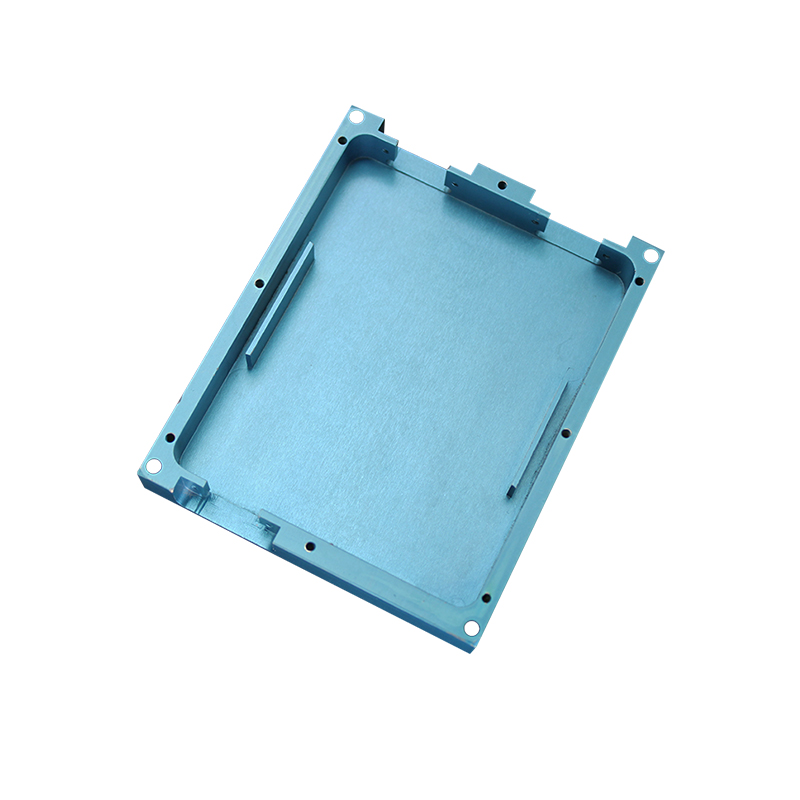

CNC Turning Services

One of the most basic machining tools, CNC turning is a practical production process for many types of parts production. Like other CNC technology, CNC turning uses computer-aided drawing (CAD) files to reproduce parts to a high degree of accuracy and precision.

What is CNC Turning Machining?

Like, CNC milling, CNC turning is used as a manufacturing process for precision parts production. Sometimes used synonymously with CNC lathe, CNC turning centers are typically more flexible, offer more tools and design options, and can produce more parts per day.

Cycles

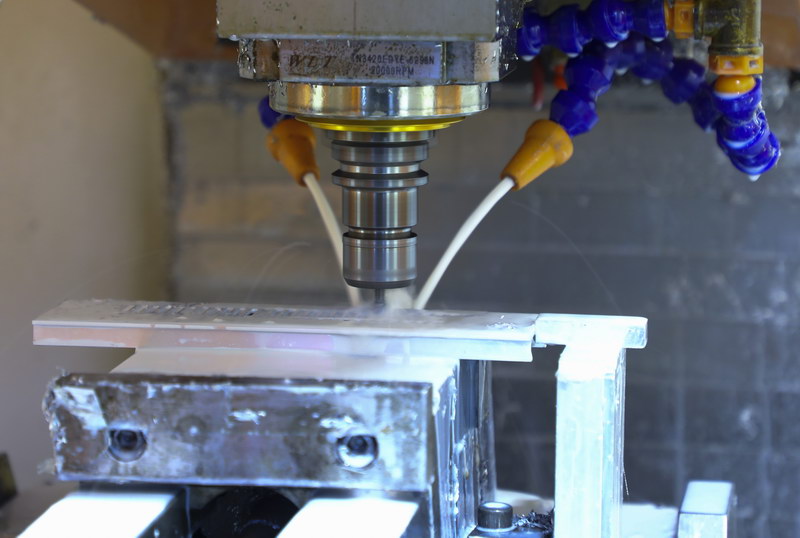

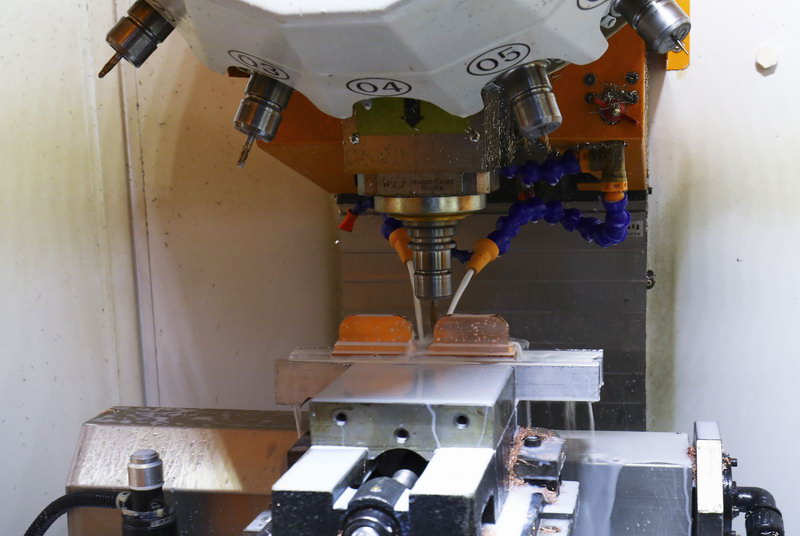

How does CNC Turning work?

Like CNC milling, a CNC turning machine holds a block of material and the mechanism rotates while material is removed to create the shape. CNC turning is typically used to manufacture cylindrical-type forms and is a straightforward process:

- CAD model is drawn on a computer by an engineer or designer.

- The CAD file is transferred into a CNC-readable program, also known as G-code. The G-code is used to setup the CNC turning center.

- The stock material is rotated on a metal rod while a CNC cutting tool removes material to the shape dictated by the software.

- Parts can be left as-machined by the CNC turning (with more visible machine marks) or bead blasted and finished smooth.

For more complex shapes and finishes, CNC turning can be combined with CNC milling and other processes.

What part types can CNC Swiss Turning produce?

CNC turning uses many different operations to create parts including facing to produce a flat surface, threading (internal and external) knurling for regular roughness on a cylinder shape, drilling and boring to make holes, and more.

Virtually any type of cylindrical, gear or rounded part can be created using CNC turning. The operation is used to manufacture parts for automotive, aerospace, agriculture, and other industries. CNC turning is used for shift knobs, auto parts, knobs, pulleys and shafts, toy parts, flywheels, hubs, disc cam, crankshafts, and more.

Why should buyers consider CNC Turning?

As a staple in precision parts manufacturer, if a part can be made using CNC turning it will result in the highest quality part against traditional or manual methods. Buyers can count on a high accuracy of each surface, stable precision regardless of the production run, fine finishing, and high quality for fine details.

CNC turning is a great technology for functional prototypes, end-use parts, cylindrical features, and parts with holes, flats, grooves, and slots. The process works quickly, efficiently, and is typically cost effective for buyers looking for large quantities. Because CNC turning is so efficient, there is minimal waste.

What materials can be used in CNC Turning?

Like all CNC machine types, CNC turning can process almost any type of material. CNC turning can produce parts from wood, plastics or metals.

Materials that can be used with a CNC milling process include:

- Woods: cherry, pine, ash, oak, and more

- Plastics: polyvinyl chloride (PVC), acrylic sheets, nylon, polycarbonate, polypropylene, PTFE, and more

- Metals and allows: steel, stainless steel, copper, aluminum, brass, and more

CNC Maching

Learn more

About us

Difference Between CNC Milling and CNC Turning

CNC Milling and CNC Turning allow users to create patterns and add detail to metals that are impossible to do by hand. CNC Milling uses commands, codes programmed into the computer and set to run. The mill then drills and turns along axes to cut materials to dimensions entered into the computer. Computer programming allows machines to make precise cuts, users can manually override the CNC Machines to slow or speed up the process.

In contrast, CNC Turning uses computer-controlled machines to create a different final product. The process uses a single-point cutting tool that inserts parallel to the material to cut. The material is rotated at changing speeds and the tool cutting traverses to create cylindrical cuts with exact measurements. It is used to create circular or tubular shares from larger material pieces. It is an automated process and speeds can be adjustments for greater accuracy rather than turning a lathe by hand.

OUR News & events

The first time know what happen in HONGFA company. We will update the last technology in custom aluminnum, meta and plasti enclosure.We design and manufacture custom enclosures for a wide range of industries and sectors. We are used to working towards specific norms and specifications.

GET TO KNOW MORE KNOWEDGE ABOUT ENCLOSURE

We offer two standard systems for enclosures of any dimension. To create these enclosures, Front Panel Designer includes a housing tool that enables you to create all the housing sections you need with just select the right accessories.