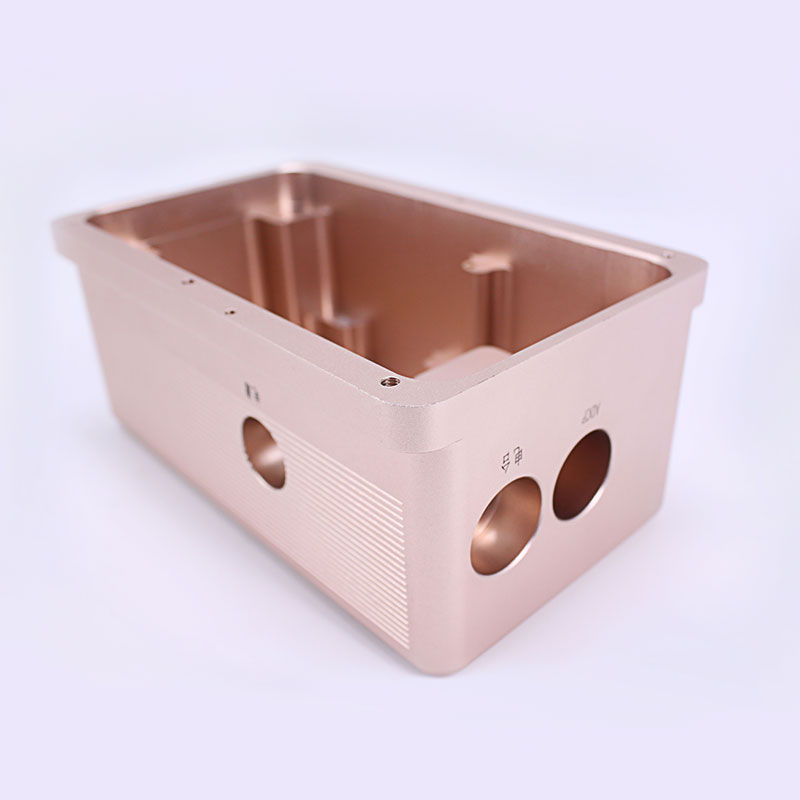

Making Aluminum Parts is Fast and Easy

Understanding CNC Milling

Home > CNC Maching > CNC Milling

Milling is the most common type of CNC machining

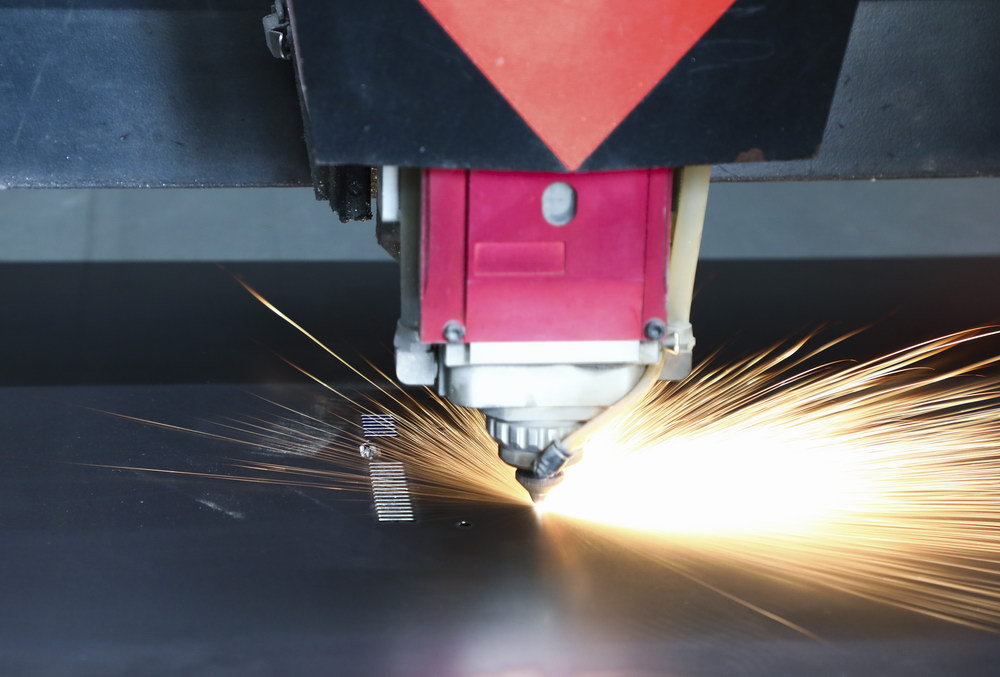

Computer Numerical Controlled (CNC) mills follow precise sets of instructions to drill or machine identical parts. CNC milling machines use computerized controls and translated codes from CAD and CAM software to perform automated machining functions on a workpiece.

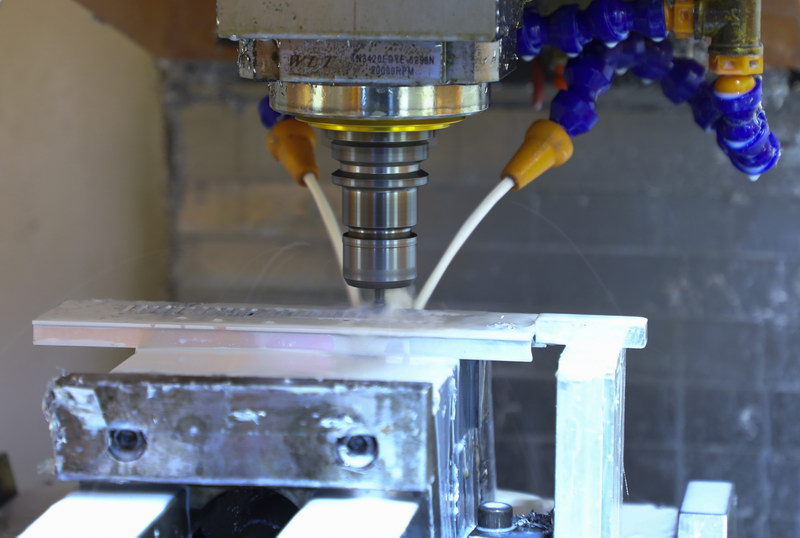

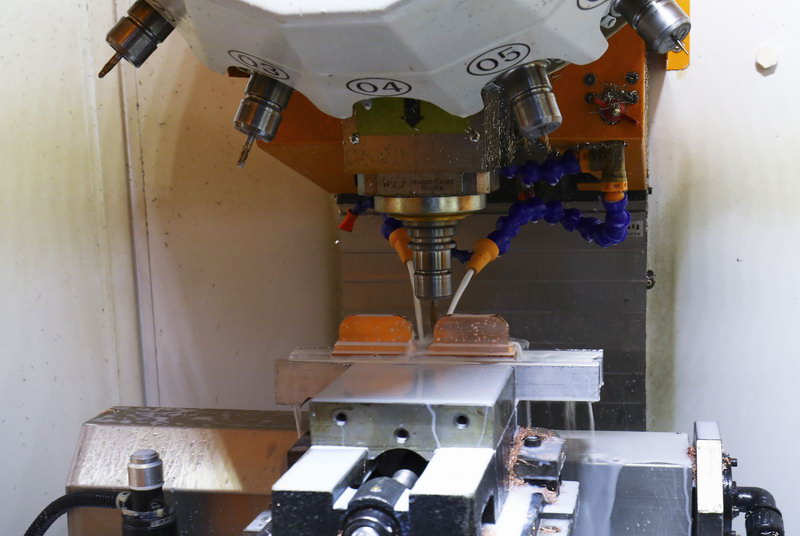

Milling is the most common type of CNC machining. The rotary cutting tools involved in the milling process remove small pieces of material from the workpiece to shape the piece or create holes. CNC milling processes can machine many different types of metal, plastics, and wood to precisely create intricate parts.

At Ardel Engineering, our CNC machining capabilities enable us to fabricate parts from complex designs for clients across a diverse range of industries.

Overview of CNC Milling Process

Like most conventional mechanical CNC machining processes, the CNC milling process utilizes computerized controls to operate and manipulate machine tools which cut and shape stock material. In addition, the process follows the same basic production stages which all CNC machining processes do, including:

- Designing a CAD model

- Converting the CAD model into a CNC program

- Setting up the CNC milling machine

- Executing the milling operation

The CNC milling process begins with the creation of a 2D or 3D CAD part design. Then the completed design is exported to a CNC-compatible file format and converted by CAM software into a CNC machine program which dictates the actions of the machine and the movements of the tooling across the workpiece. Before the operator runs the CNC program, they prepare the CNC milling machine by affixing the workpiece to the machine’s work surface (i.e., worktable) or workholding device (e.g., vise), and attaching the milling tools to the machine spindle. The CNC milling process employs horizontal or vertical CNC-enabled milling machines—depending on the specifications and requirements of the milling application—and rotating multi-point (i.e., multi-toothed) cutting tools, such as mills and drills. When the machine is ready, the operator launches the program via the machine interface prompting the machine to execute the milling operation.

OUR News & events

The first time know what happen in HONGFA company. We will update the last technology in custom aluminnum, meta and plasti enclosure.We design and manufacture custom enclosures for a wide range of industries and sectors. We are used to working towards specific norms and specifications.

GET TO KNOW MORE KNOWEDGE ABOUT ENCLOSURE

We offer two standard systems for enclosures of any dimension. To create these enclosures, Front Panel Designer includes a housing tool that enables you to create all the housing sections you need with just select the right accessories.