DESIGN & PROFESSIONAL

Enclosure Manufacturing Services

Home > Services

Design Finished Enclosure

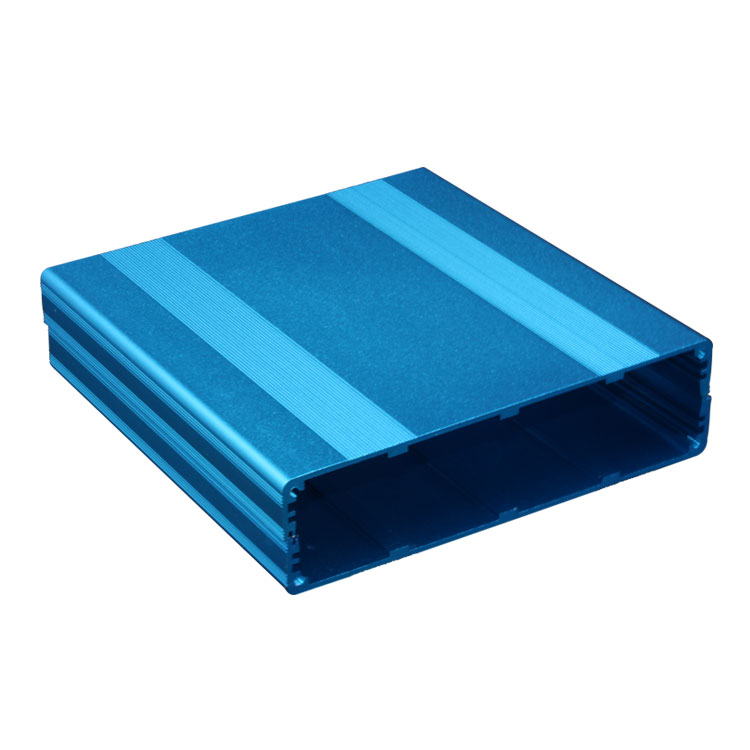

The extruded aluminum enclosures are made through extruded molds,the mateiral is 6063 aluminum alloy,the width and height of the case are constant,can not be changed,but the length can be cut to any size ( within 3m).A complete aluminum enclosure including extrusion housing,two end covers and screws.

The sheet metal parts processed generally made by bending or punching some thin metal sheets to deformation, to form the desired shape and size, and can further form more complex parts by welding or a small amount of machining metal sheet (usually within 6mm).

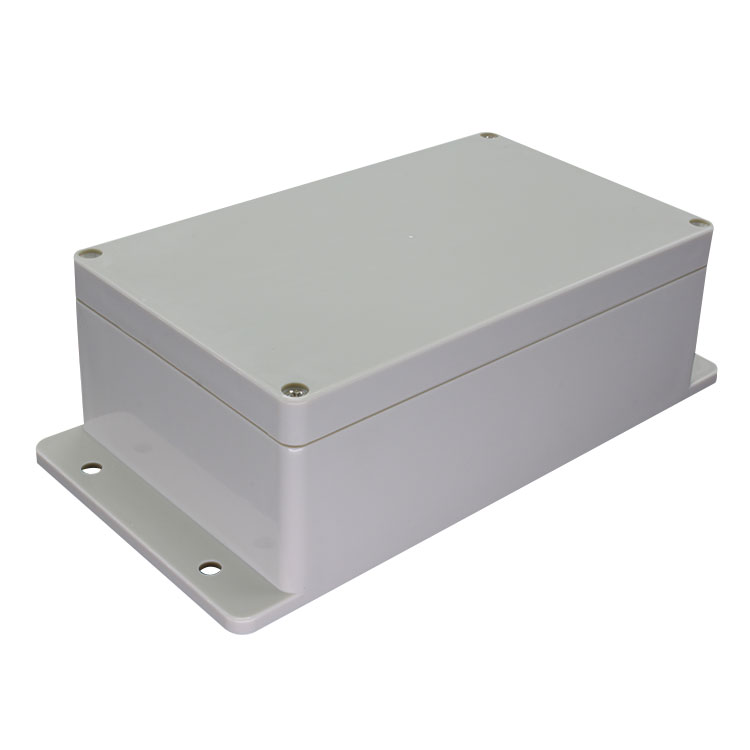

The electronic case can protect your components in any environment. Hongfa Shunda offers different series of electronic boxes and multi-purpose metal and plastic electronic cases. Superior environmental protection materials include high-quality ABS, PC, aluminum, iron, etc. From indoor to outdoor, from on the ground to hang on the wall, you can find the perfect box here.

How to order a customized electronic enclosures from Hongfa?

Different material enclosures have different customization processes

For plastic enclosure,it is made through injection mold.If you choose the existing plastic box from our catalog,only add simple processing such as drill holes,print logos,there’s no MOQ,simple drawing is ok.But to build a new plastic enclosure, we first need to make an injection mold. Detailed 3D drawings are necessary or need a sample. Our company prefers to use drawings in 3D STP format.To make new mold,there’s MOQ.

For aluminum extruded enclosure,if choose a existing part,there’s also no MOQ,we can cut length,drill holes,change colors and print logos etc.But to build a new extrusion aluminum,also need to make mold,then will have MOQ.No matter choose add processing on existing aluminum box or make new mold,2D drawing is necessay.

For sheet metal parts.The sheet metal parts refer to the products or parts produced by the combination of the bending, riveting, precision welding, forming and other processes of the metal sheet after laser cutting or stamping.Usually there’s no MOQ. We make it easy as possible for you by offering a one-stop source for custom, fully finished precision sheet metal parts. Choose from a variety of materials, hardware, fasteners, and powdercoat colors to fully finish your custom sheet metal part. Add graphics such as a logo or labeling with our direct digital printing and silkscreen services.

OUR NEWS & EVENTS

The first time know what happen in HONGFA company. We will update the last technology in custom aluminnum, meta and plasti enclosure.We design and manufacture custom enclosures for a wide range of industries and sectors. We are used to working towards specific norms and specifications.

GET TO KNOW MORE KNOWEDGE ABOUT ENCLOSURE

We offer two standard systems for enclosures of any dimension. To create these enclosures, Front Panel Designer includes a housing tool that enables you to create all the housing sections you need with just select the right accessories.