DESIGN & PROFESSIONAL

Plastic Enclosure Manufacturing for Electronics Cases

Custom Electronics Cases Enclosure

Design and making your exact specifications in 7-10days. (China Manufacturer)

Shipping from China by air for your sample, shipping time: 3-5 Days.

MAKING SOLUTIONS FOR THE INDUSTRIAL ELECTRONICS

Plastic enclosure is used in all aspects of life because of its strong insulation. Compared with metal materials, plastic materials are not only cheaper, ensure safety, but also have strong insulation properties. Hongfa mainly produce plastic injection case,the mainly material is ABS/PC.

Hongfa have thousands of models plastic enclosures in stock,for different application,such as waterproof junction box,desktop enclosure,handheld plastic enclosures,network plastic case,small plastic enclosures, PCB enclosures for electronics devices,din rail enclosures etc.

Different Application with Plastic Enclosures

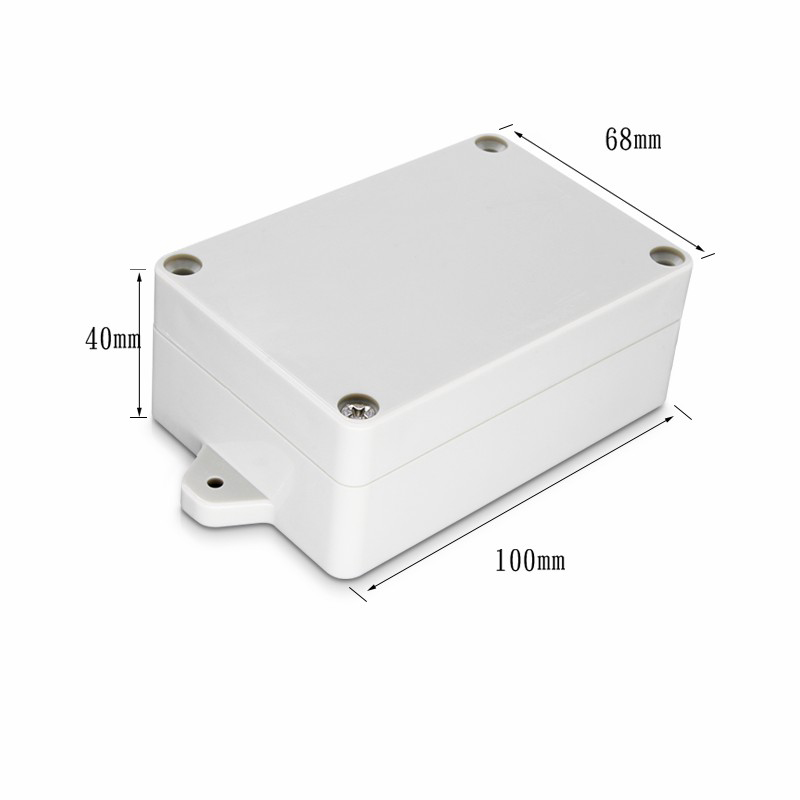

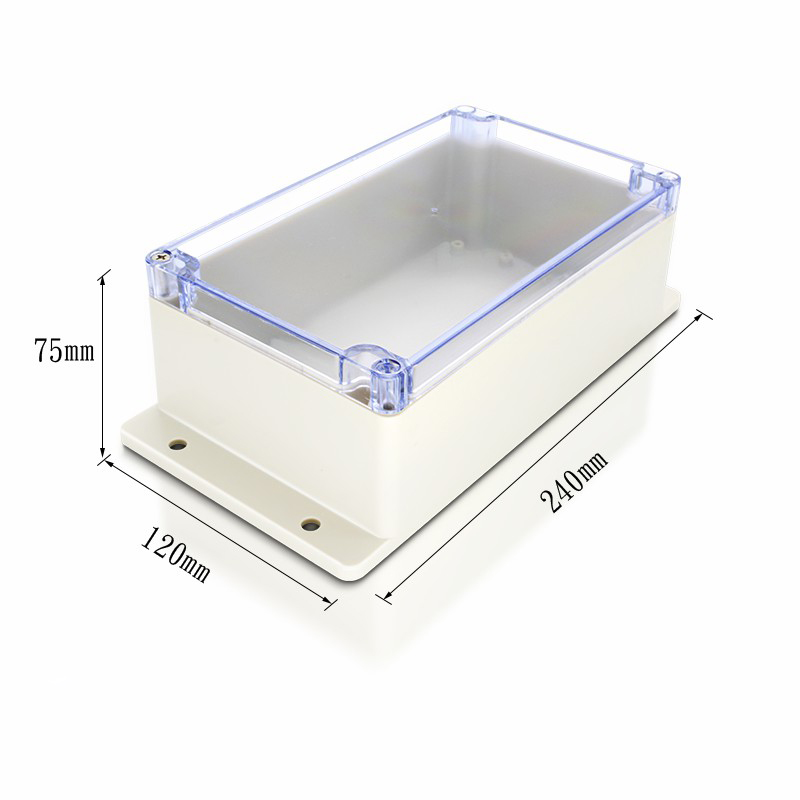

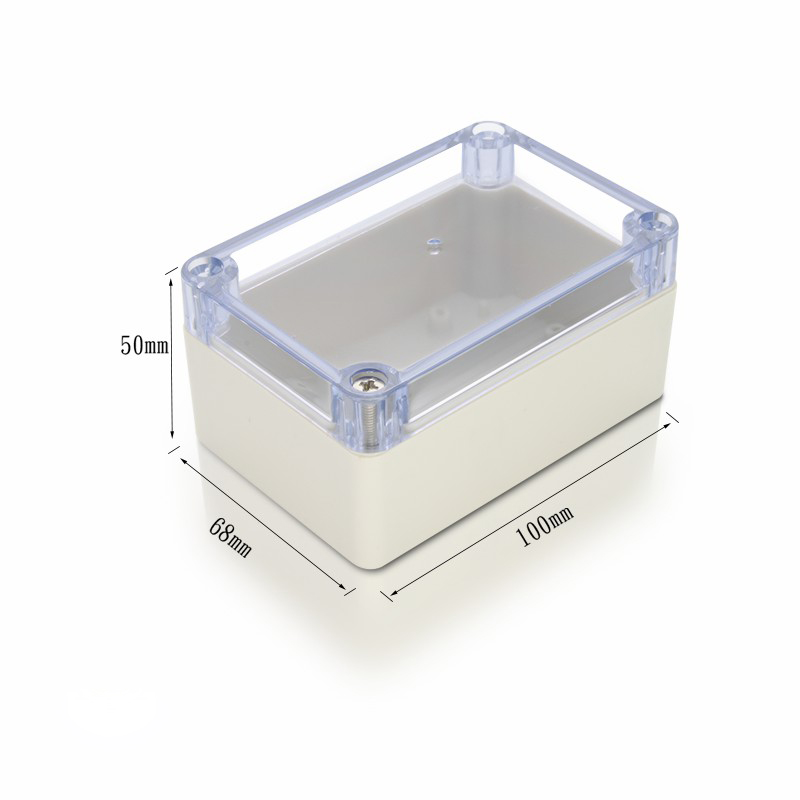

Waterproof junction box is the main enclosures,,used ABS material, IP65 protection class for sure protection for industrial wiring, relay for motors or sensors. There’re four types,normal type,wall mount type,transparent type etc.

Multipurpose plastic desktop cases and project boxes for a variety of usage. Affordably priced and easily customizable. Suitable for measuring instruments, controllers, network devices, data loggers, and medical equipment.

Network plastic enclosures has unique design, beautiful appearance and smooth surface, which is suitable for various network cases, routers, audio equipment, etc.

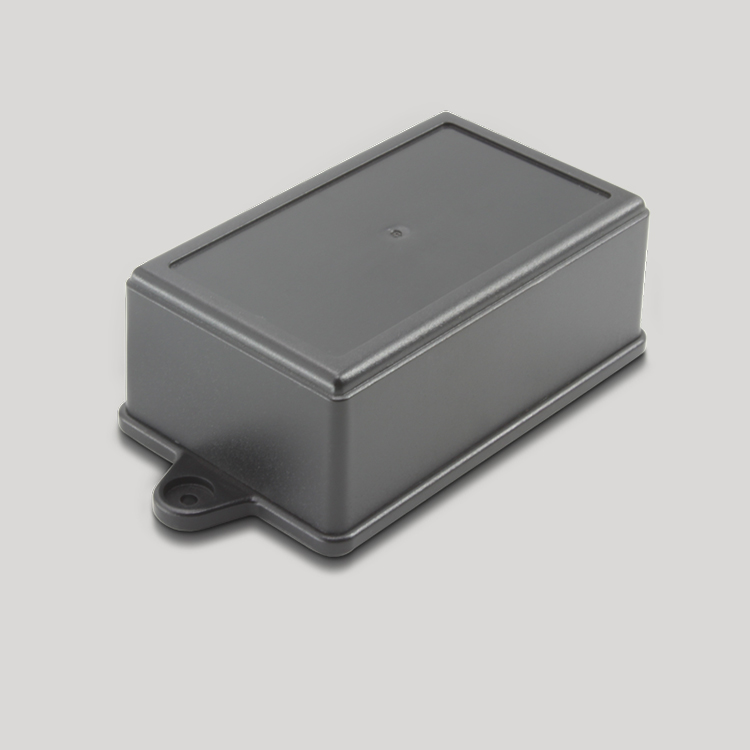

The small plastic case is mainly used as a small junction box and PCB housing. There are two types: buckle fixing and screw fixing.

Other application enclosures,such as gas sensor enclosure,door access case,handheld enclosures and din rail enclosures.

Customization service

We supply customization service for the existing models,such as drilling holes,printing logos,painting,different colors etc.

Hongfa can build the new plastic enclosures for you if the exixting models do not fit your product. Conditions for opening plastic molds: 3D structure product drawings or physical samples of PCB board. For the drawing,we prefer 3D STP format.To build a new plastic box,there’s mold fee and MOQ for product.

Design Finished Enclosure

Why Choose HongFa?

For 14 years, Hongfa has been a leader in the design and production of shell products. As the market demand for shell products continues to rise, Hongfa is also growing.

With the development of global technology, our customers’ continuous repurchase is the proof of Hongfa’s service culture. While we focus on our customers, we also know that our employees are an important part of Hongfa’s continued success and future.

Hongfa hopes that every employee can achieve success and develop his valuable career. That’s why one of our core values is to pursue personal and corporate development, because we know that when you succeed, we will all succeed.

OUR NEWS & EVENTS

The first time know what happen in HONGFA company. We will update the last technology in custom aluminnum, meta and plasti enclosure.We design and manufacture custom enclosures for a wide range of industries and sectors. We are used to working towards specific norms and specifications.

GET TO KNOW MORE KNOWEDGE ABOUT ENCLOSURE

We offer two standard systems for enclosures of any dimension. To create these enclosures, Front Panel Designer includes a housing tool that enables you to create all the housing sections you need with just select the right accessories.