Aluminum profile usually refers to the profile formed by aluminum alloy material through melting and casting and extrusion.

Melting and casting is the first process of aluminum production, and the main processes are

(1) Batching: According to the specific alloy grades to be produced, the amount of various alloy components to be added is calculated and various raw materials are reasonably matched.

(2) Smelting: The raw materials are added to the melting furnace and melted according to the process requirements, and the molten slag and gas are effectively removed by means of de-gassing and dross refining.

(3) Casting: Under certain casting process conditions, the melted aluminum liquid is cooled and cast into various specifications of round cast bars through deep well casting system.

The round aluminum rods formed by melting and casting will be extruded from the mold through the mold and extruder designed and manufactured according to the section of the profile products. The commonly used grade is 6063 alloy, and the extrusion is accompanied by an air-cooled quenching process and a subsequent artificial aging process to complete the heat treatment strengthening.

The finished aluminum profile has the following characteristics.

- corrosion resistance.

The density of aluminum profiles is only 2.7 g/cm3, about one-third of that of steel, copper or brass. In most environments, including air, water (or salt water), petrochemical and many chemical systems, aluminum can show excellent corrosion resistance.

- Non-ferromagnetic

Aluminum profiles are non-ferromagnetic, which is an important characteristic for the electrical and electronic industries. Aluminum profiles are not spontaneously combustible, which is important for applications involving handling or contact with flammable and explosive materials.

- Machinability

Aluminum profiles have excellent machinability. In various deformed and cast aluminum alloys, and in various states after the output of these alloys, the machinability varies considerably, which means that special machine tools or techniques are required.

4.Formability

The specific tensile strength, yield strength, ductility and corresponding work hardening rate govern the variation in the amount of deformation allowed.

5.Recyclability

Aluminum is highly recyclable and the properties of recycled aluminum are almost indistinguishable from those of virgin aluminum.

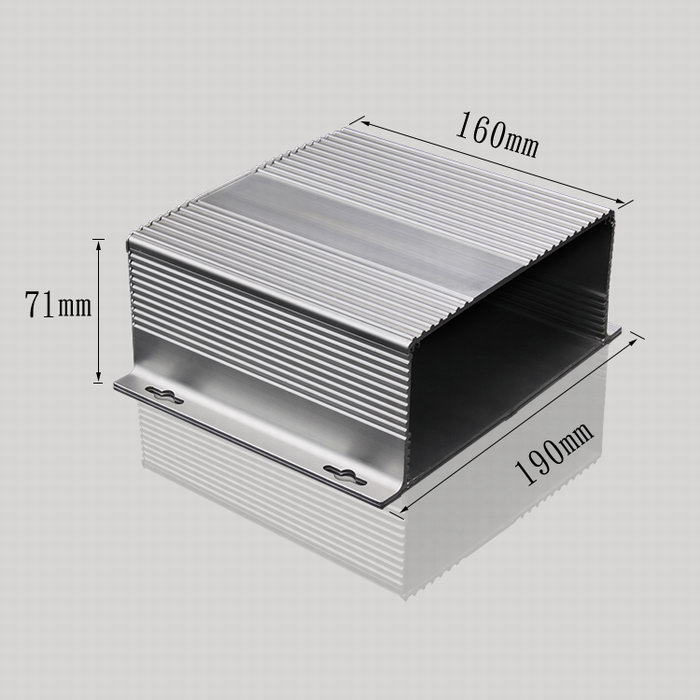

The formed profile is then cut, perforated and surface treated to form the finished case according to the customer’s OEM needs. Among these, surface treatment is a step that can directly affect the appearance of the finished product. Hongfa Shunda Mould Co., Ltd. can produce dioxygen, oxidation sandblasting and oxidation powder surface treatment according to customer’s requirements.

Finished aluminum profile cases combined with electronic components are widely used in industry, construction, sensors, smart home and other fields.

As the world’s largest developing country, China’s stable, continuous and rapid development of national economy and high technology has led to the rapid development of aluminum smelting and aluminum profile processing industry in China. The output of aluminum profiles in China has reached 8.793 million tons in 2006, surpassing the United States to become the world’s first; in 2007, the output was as high as 12.508 million tons, up 42.45% year-on-year, hitting a new record high.

In the 21st century, China’s aluminum processing industry closely combined with the market and the needs of scientific development, so that the traditional aluminum processing materials have gradually completed the transformation to modern aluminum processing materials, so China’s aluminum processing material varieties have undergone great changes.

The important feature of China’s aluminum processing material is to develop in the direction of high performance, high precision, energy saving and environmental protection, many products have become famous brands at home and abroad and enjoy a good reputation in domestic and international markets; the quality of products has been steadily improved, the level of product standards has been in the ranks of international advanced, the main aluminum manufacturers in addition to the national standard production, are able to directly accept orders according to the requirements of the world’s advanced national standards. This shows that China’s aluminum processing material production has been further internationalized, and in order to meet the national economy and science and technology to high precision aluminum demand in many aspects, the main aluminum processing enterprises also correspondingly developed a lot of internal supply technology standards.

There are about 300 alloys and 1500 varieties of aluminum processing materials in China, which is one of the countries with the most abundant product varieties in the world. Among the many varieties of aluminum processing materials, a large number of international advanced products and national famous brand products have emerged, representing the mainstream direction of the development and application of modern aluminum processing technology in China.